“Y“-type blades

Top technology

for outstanding results

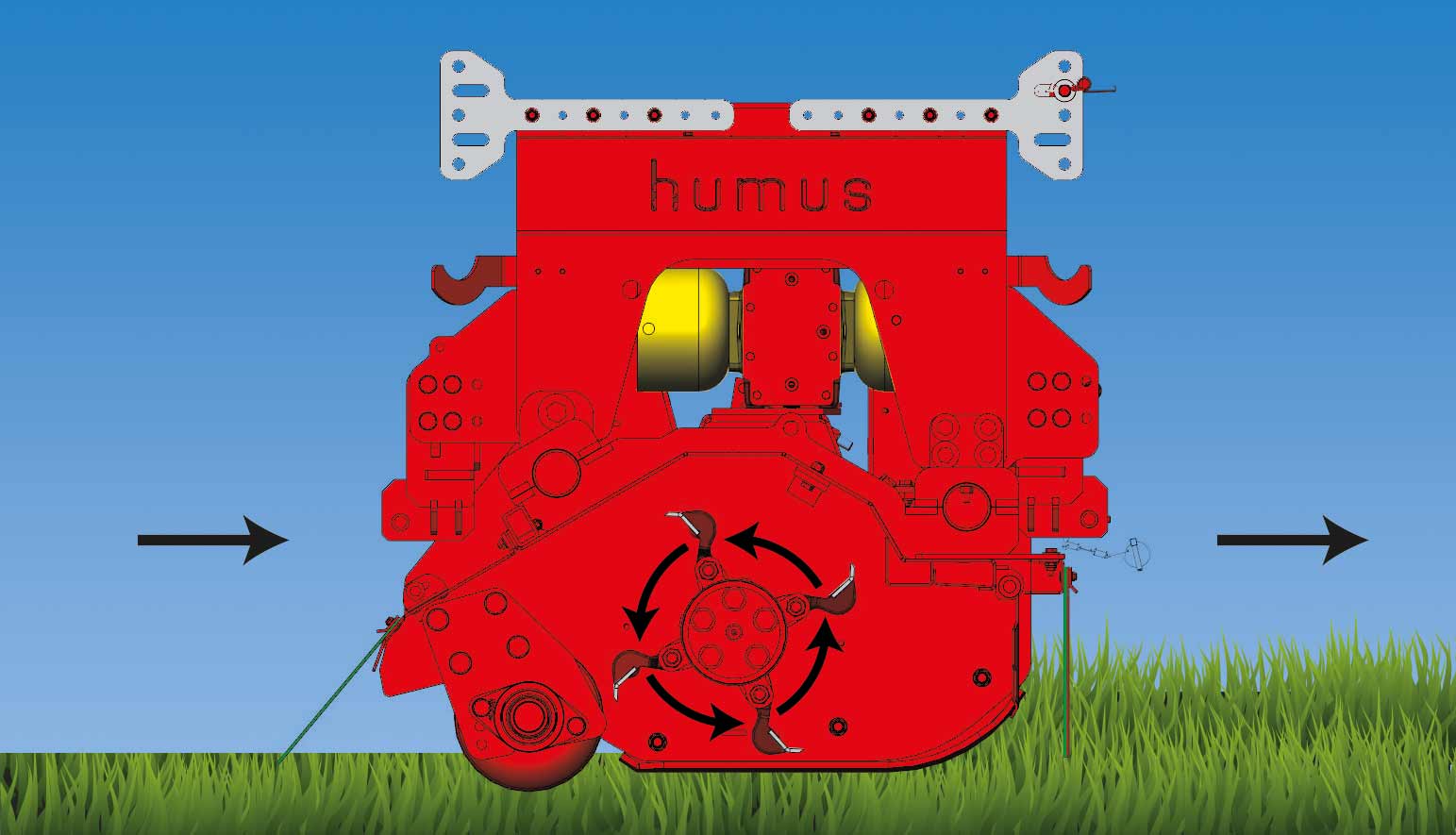

The mode of operation of all humus flail mulchers: On the electronically-dynamically balanced rotor shaft with a generously configured spherical roller bearing the cutters are arranged so that they can oscillate freely and overlap. The cutters mulch the growth at the individually adjustable height and convey the mulched material through the tearing bars – here fine defibration and reduction occur.

The mulched material is routed along the housing via the track roller and is uniformly distributed behind the flail mower. The humus flail mulchers are either equipped with “Y“-type blades or with flails depending on the application:

The blades that are suspended in pairs are free-moving, durable and require only minimal force. Moreover they ensure good distribution of the mulch mass. They can be used on both sides and are very popular because they generate minimal dust when they are working.

Recommended implementation areas

- Green area maintenance

- Branches to 5 cm Ø

- Shrubbery

- On rocky ground

- In row cultures

- Mulching in green manure

System flail

Due to its special shape and high net weight 2,7 kg, the system flail develops an advantageous suction effect and a particularly attractive cutting pattern. Either a fine-cutting blade or a claw blade is screwed into the deep bed of the cutter carrier. The blades can be cost-effectively replaced.

Recommended implementation areas

…for fine-cutting blades

- Pasture care

- Shredding timber to approx. 10 cm Ø

- Green area maintenance

- Field work

- Forestry applications

- Mulching of corn stover

…for claw blades

- Shredding timber to approx. 10 cm Ø

System flail for PM

Due to its special shape and high net weight 4,6 kg (PM) and 4,2 kg (PMG), the system flail develops an advantageous suction effect and a particularly attractive cutting pattern. Either a fine-cutting blade or a claw blade is screwed into the deep bed of the cutter carrier. The blades can be cost-effectively replaced.

Recommended implementation areas

…for fine-cutting blades

- Pasture care

- Shredding timber to approx. 10 cm Ø

- Green area maintenance

- Field work

- Forestry applications

- Mulching of corn stover

Fine-cutting blade B60

Small flails

Like its big brother, the system flail, due to its special shape and high deadweight, the fine-cutting blade B60 develops an advantageous suction effect and a particularly attractive cutting pattern. A fine-cutting blade is screwed into the deep bed of the cutter carrier. The blades can be cost-effectively replaced.

Models SM, SMH, SSP 125 to 155, SME and SSG are available with the B60 fine-cut blade, flail cutters, or as safety mulchers. They ensure a clean and good cut when mulching and really prove themselves when shredding shrubbery to a thickness of 3 cm.

Recommended implementation areas

- Mulching of grass

- Parks and athletic facilities

- Roadsides and waysides

- Dams and dikes

- Municipal use

- Shredding timber to approx. 3 cm Ø

Universal flail

This is an all-round flail. It equally suited for mulching and for shredding wood to a thickness of approx. 5 cm.

B70

Only suitable for the PH underbrush mulcher!

B80

Only suitable for the PH underbrush mulcher!

The B70 cutter is the ideal partner for tasks with light ground contact! Thanks to its single-edged, sharp and hardened blade, you obtain the best fine-chopping results. The B70 cutter is suitable for all ground conditions, all types of vegetation and all types of undergrowth strata.

Triple-edged carbide tool with offset cutting edges for wear-intensive and sandy applications. Minimal force requirement thanks to diagonally inserted carbide plates and an additional wear guard on the holder.

Recommended implementation areas

- Mulching of undergrowth and multi-year growth

- Embankment maintenance

- Line maintenance

- Biotope maintenance

- Renaturation

- Recultivation

- Maintenance of bushy areas

- Area management and landscape management

B40/B50

Only suitable for PS

A worm shaft is at the centre of the safety mulcher technology. It is equipped with multi-toothed cutting blades made of highly wear-resistant special steel. The B50 variant is a reinforced version of this cutting blade system, which is intended to cover a very wide range of applications. When mulching, a particularly clean and fine cutting pattern can be achieved with a high area performance and it also convinces with excellent results when shredding brushwood and wood. The special design and arrangement of the blades on the rotor virtually prevents stones and foreign objects from being thrown out during work and also when lifting the mulcher.

Also available as B40 with carbide tipped blades for wear-intensive and sandy applications!