65 years innovative

For more than 65 years humus has stood for innovative mulching technology in orchards and vineyards and municipal green area maintenance.

Our history

Since 1954 when we developed the first mulcher for orchards, we have successfully pursued this theme. Today the humus product range includes more than 100 models.

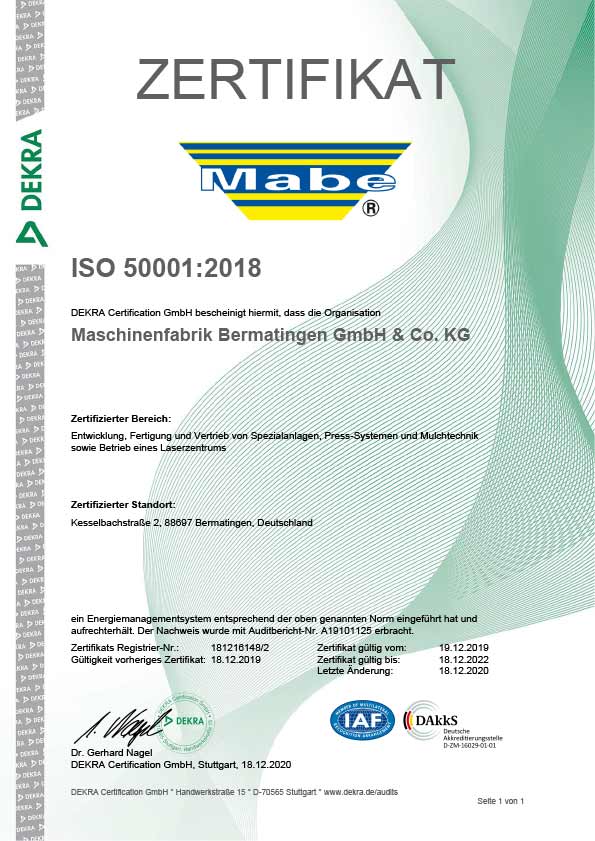

Now for more than 65 years the name, Maschinenfabrik Bermatingen, has been a guarantee of competence and innovation. Our expenditures for research and development are at a very high level. In all segments, we constantly strive to adapt our products to the requirements of our customers and thus to the requirements of the market.

In this process the considerations of our designers always go in two directions: On one hand the goal is to implement perfect technical solutions with the development of easy-to-operate machines and equipment, on the other hand the multifaceted requirements that enable environmentally responsible behaviour must be taken into account.

Our machines are developed from two perspectives. The needs of the customer and the best possible quality. As an environmentally conscious company, we only produce in Germany, more precisely in Bermatingen, where our 4 plants are located.

We are proud of the diversification of our brands. DIXI baling presses, the perfect system for reducing the volume of recyclable materials, humus mulchers that have often received awards in the agricultural and municipal sectors and the Bermatingen laser center as a modern service provider in the metal construction sector.Roderich Gotterbarm

»We have grown up with the development and production of mulchers. Today, the machines offered under the brand name humus are standard equipment in orchards and vineyards, municipal implementation and forestry applications.«

Modern manufacturing assures a high standard of quality

All the operations of the enterprise are centralised in at the company’s headquarters facilities in Bermatingen on Lake Constance: Administration, development, parts manufacturing and final assembly work together transparently. The biggest milestone in the company’s history was reached by the construction of the new company headquarters. This allowed the previous production area of 9,000 square meters to be expanded to the current production area of over 15,600 square meters.

Know-how

With team spirit and commitment, qualified and motivated employees ensure the achievement of our ambitious corporate goals. We know: If you want to be a top player, you must be prepared to achieve something extraordinary.

We act accordingly: Through ongoing investment we guarantee the high quality standard of our products. Systematic inspections and test accompany all phases, from the development to all stages of manufacturing to shipment to our customers throughout the world.

Precision work for satisfied customers

In our company it is not just all products that are in-house designs or that are developed by ourselves to series production readiness, we also produce all component parts ourself – to the extent possible and to the extent that appears profitable for us. Trained employees operate state-of-the-art manufacturing equipment.

In addition to the laser centre (www.laserschneiden.tv) our CNCcontrolled welding robots and trimming presses comprise another important prerequisite for smoothly and sustainably fulfilling our own quality requirements and the high quality expectations of our customers. In our own paint shops our product receive the protective paint finish.

Likewise, when installing standard parts we also impose high quality requirements and only use products that meet international standards.