Leaving a 40 cm blossom strip standing

OMBfor tractors from 45 hp

Especially designed for the cultivation of the blossom strip in orchards

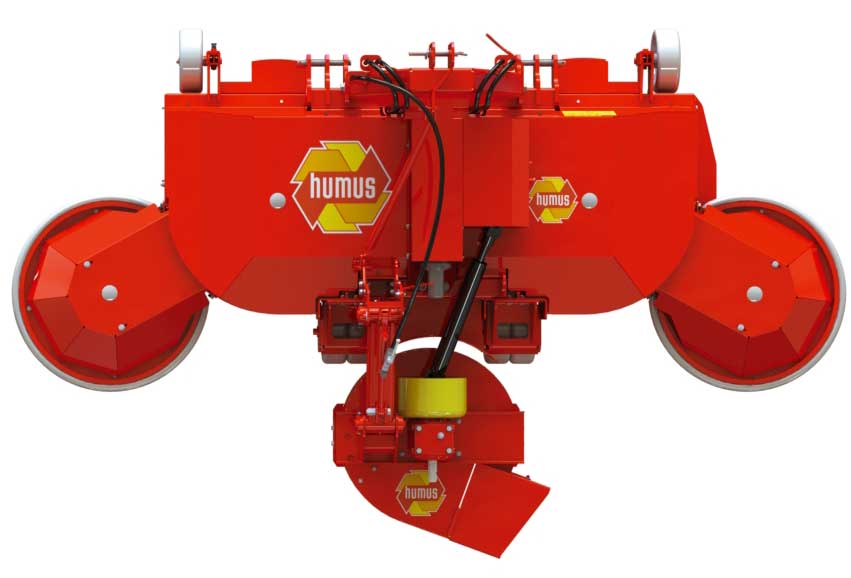

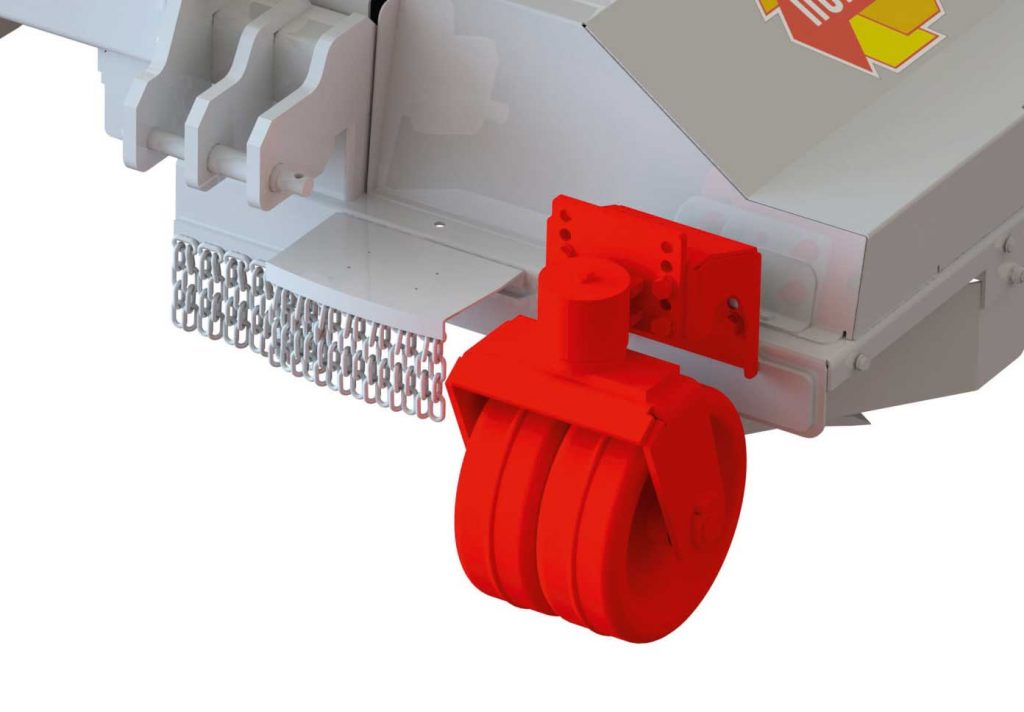

Beneficial insects (e.g. bees, butterflies) and predators of aphids and spider mites (ladybugs, aphid lions) are encouraged through blossom strips with indigenous flowering meadow plants and wild herbs in orchards. Through its lift-out rotary cutter the humus OMB enables the user to leave a 40 cm blossom strip standing. Likewise, scarification of the blossom strip (mulching the flower heads to stimulate growth) is also possible. Before harvesting fruit and in the headland the rotary cutter can be lowered, so the complete width of the row can be mulched.

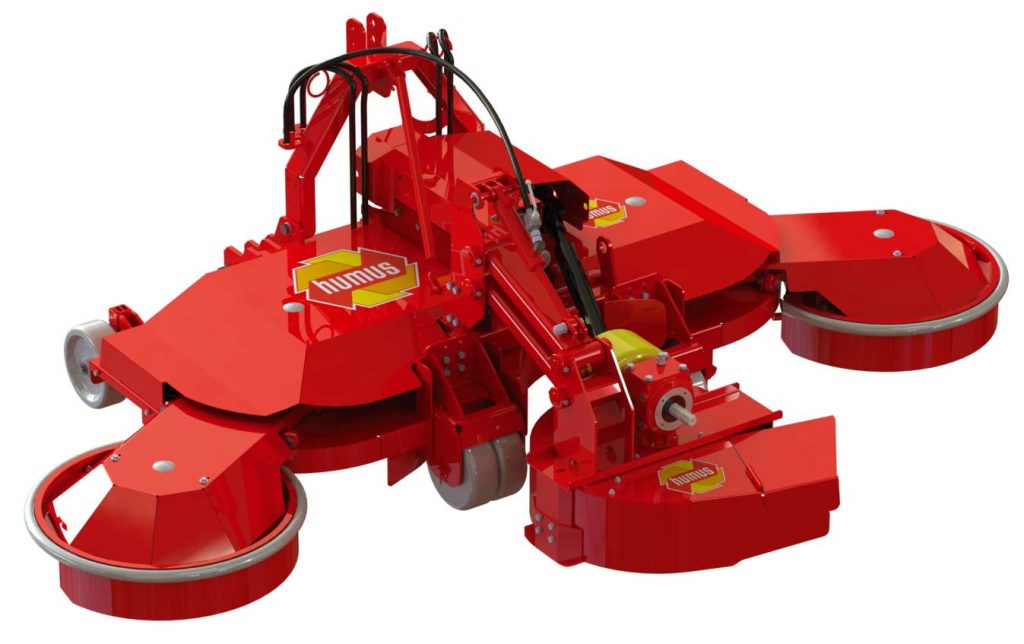

With the humus OMB any desired working position can be freely selected, thanks to its solid design and its variable working width adjustment of 2.19 m to 3.07 m. The working width is infinitely variable and hydraulically adjusted from the tractor. Both swing discs can be adjusted synchronously or separately. Thus the OMB rotary mulcher offers an absolutely reliable and economic possibility for mulching the tree strip and implementing organic cultivation. Thanks to its smooth surface, the OMB slides easily under low-hanging branches.

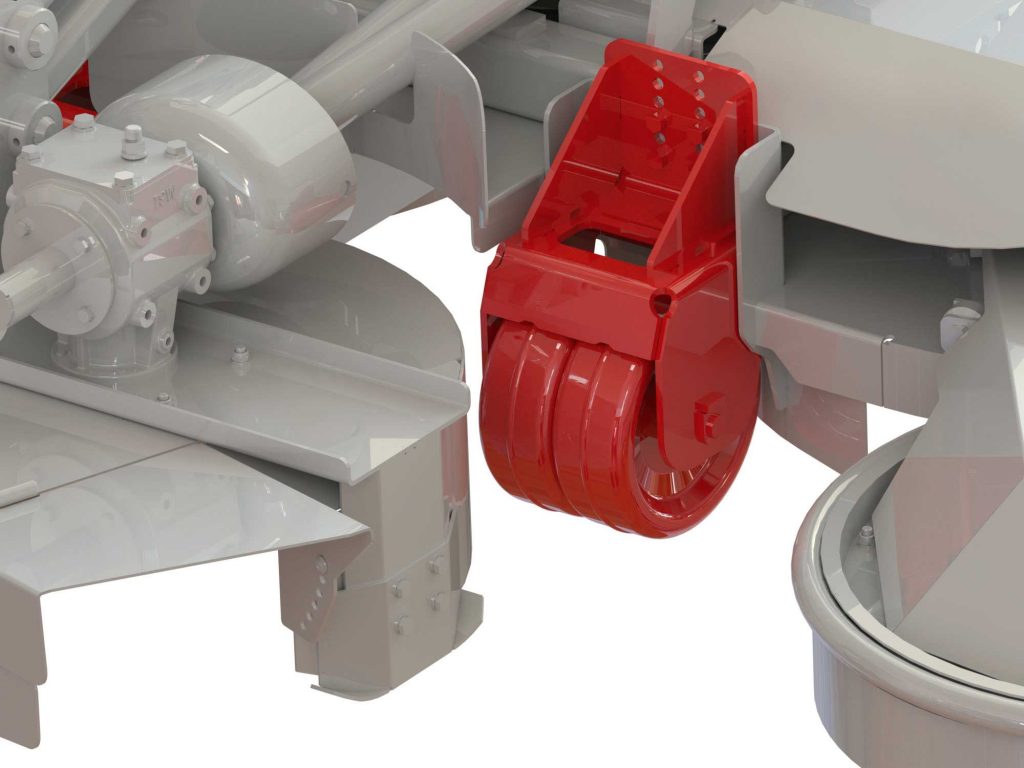

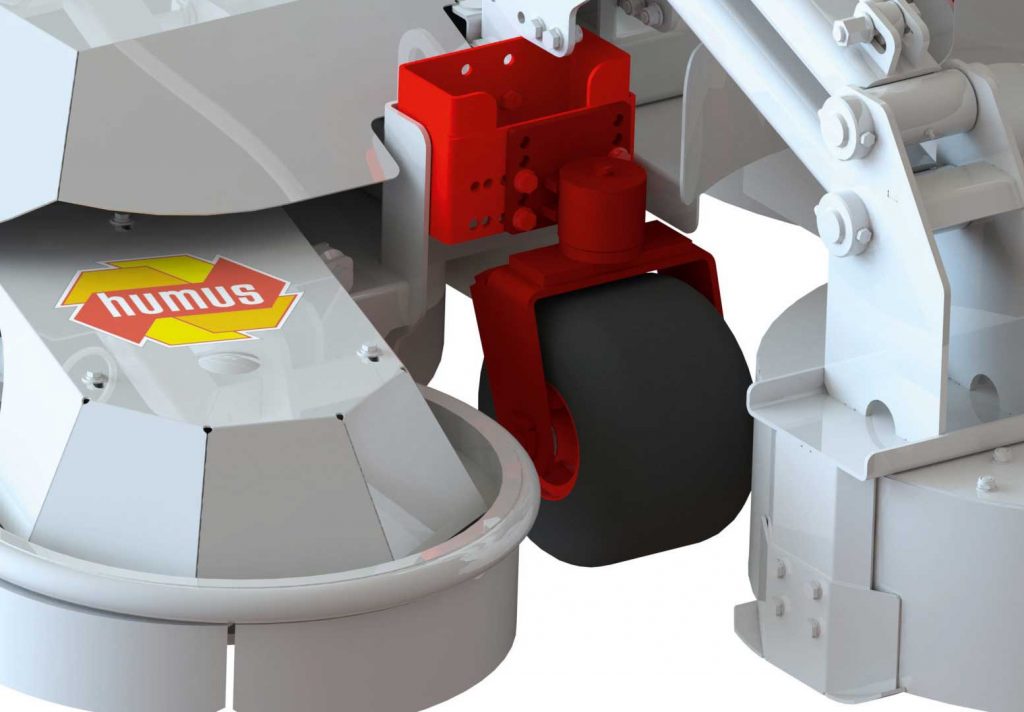

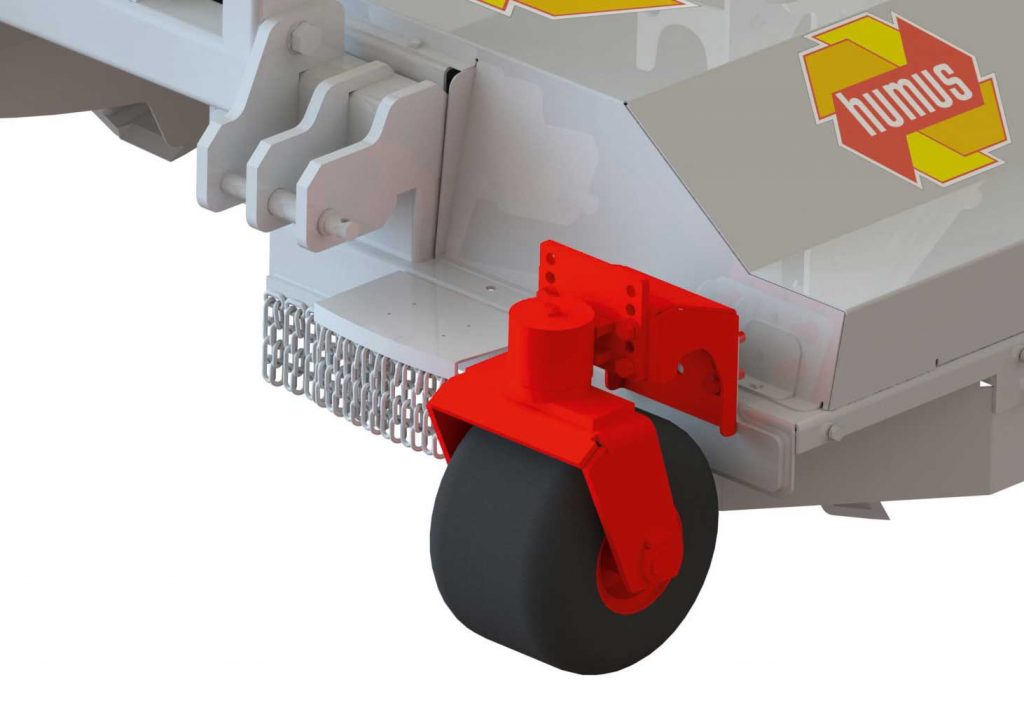

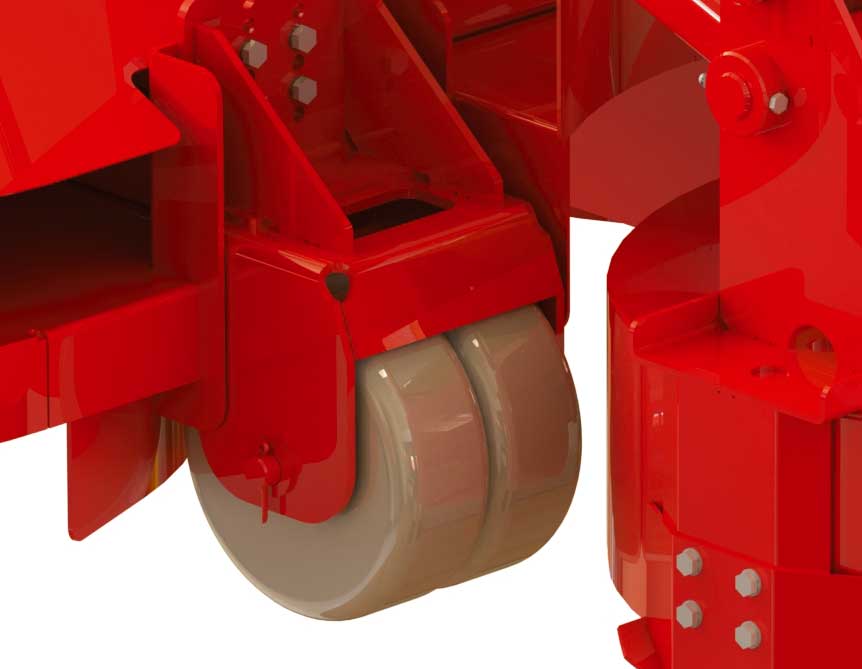

The OMB rotary mulchers move on large track wheels with a wide contact area. They can be adjusted in height.

The humus OMB has a minimal power requirement and can be operated starting at 45 hp.

Description

Well proven range of use

- ecological fruit-growing

- ecological wine-growing

Basic equipment

- Mounting: rear

- 3-point linkage Cat. I and II

- Hydraulic variable blossom strip cutting height adjustment (30–350 mm at basic implement cutting height 30 mm)

- Cutting height adjustment (basic implement) via height-adjustable track wheels

- Accident prevention guards

- Double-acting hydraulic cylinders for variable working width adjustment

- Adjusting the wings synchronously or separately

- Extending mulching head for the cultivation of a blossom strip of 40 cm

- Sliding plate under the swivel arms for height guidance and cut guidance

Accessories / special equipment

- PTO/PTO with overrunning clutch

- Two-sided hydraulic fine control with electrical remote control

- Electrical positioning

- Adapter cable from cigarette lighter to 3-pin plug (part no. 871.20.038)

- Start-up safeguard for both swing arms (not to be mixed up with microfuse)

- Control block with two double-acting control devices for swivelling the two swivel arms and one single-acting control device for lifting/lowering the blossom strip mulching head (not required, if two double-acting control devices and one single-acting control device are present on the tractor).

Technical data

OMB 2800 | OMB 2800 | OMB 3500 | ||||||

|---|---|---|---|---|---|---|---|---|

| Working width : | m | 2,07 – 2,85 | 2,25 – 3,10 | 2,56 – 3,49 | ||||

| Basic OMB without wings : | m | 1,96 | 1,96 | 1,96 | ||||

| Device width: | m | 2,20 – 2,95 | 2,37 - 3,22 | 2,65 - 3,57 | ||||

| Width of blossom strip: | cm | 40 | 40 | 40 | ||||

| Power requirement* : | from kW / hp | 37 / 45 | 37 / 45 | 37 / 45 | ||||

| Rpm of PTO: | rpm | 540 or 1.000 | ||||||

| Weight** : | approx. kg | 718 | 750 | 810 | ||||

* der Kraftbedarf ist auch von der Grasdichte und Grashöhe abhängig | ** Gewicht je nach Ausrüstung abweichend

The OMB basic implement is equipped with 3 rotary cutters. Thus a large overlap can be achieved, if desired.

The cutters are mounted on cutter carriers so that the blades can be cost-efficiently replaced. It is important to leave the mulching material long-fibred and to ensure a deposit of the cuttings in the tree strip. The mulched material should cover the open tree strip and serve as a protection against drying out and as nutrient supply.

Standard equipment

Special equipment

Variable working width adjustment

Blossom strip cutting height adjustment

Cutting height adjustment via height-adjustable track wheels