Click on the picture of the blade for more details

PHfor tractors from 54 hp

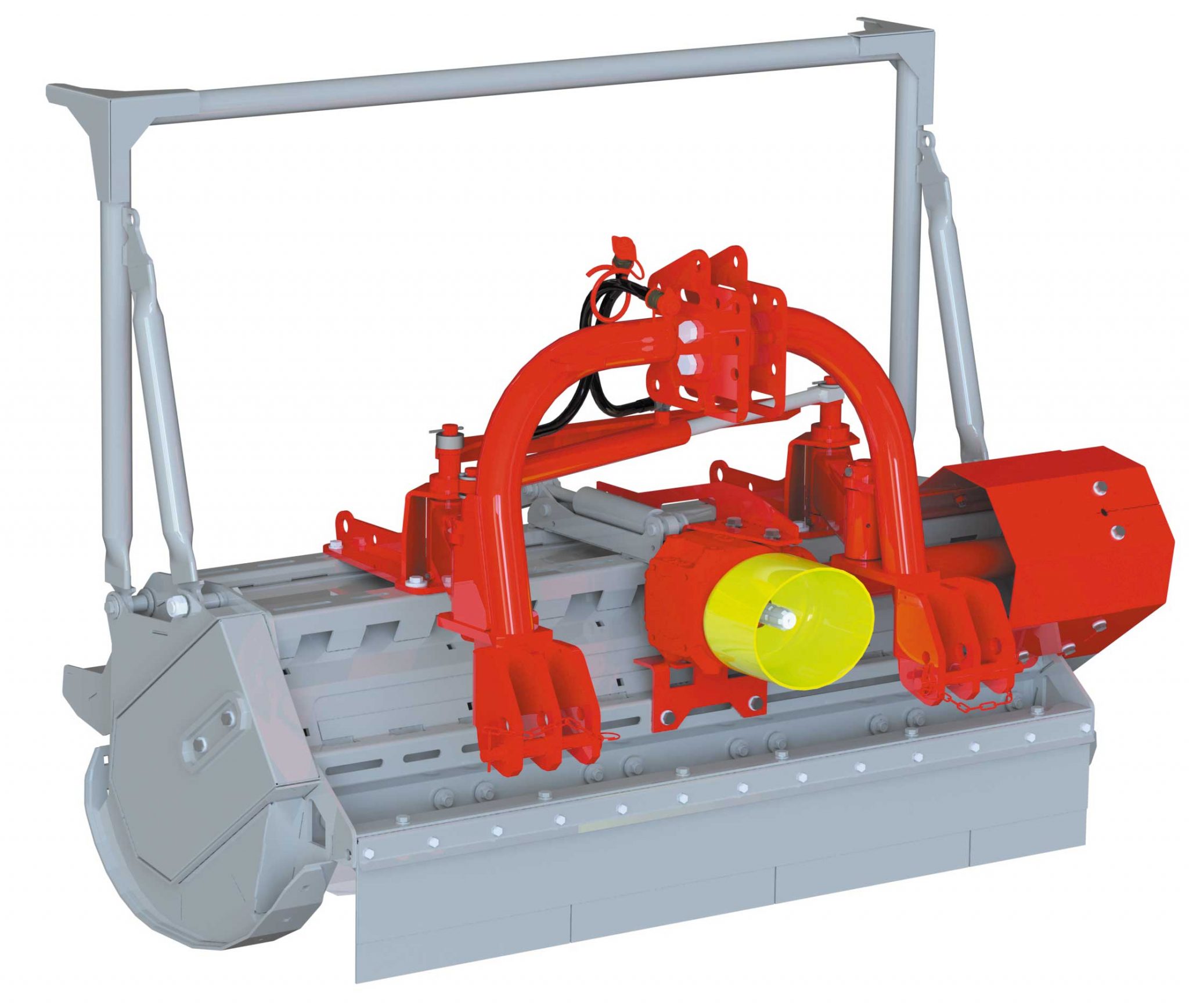

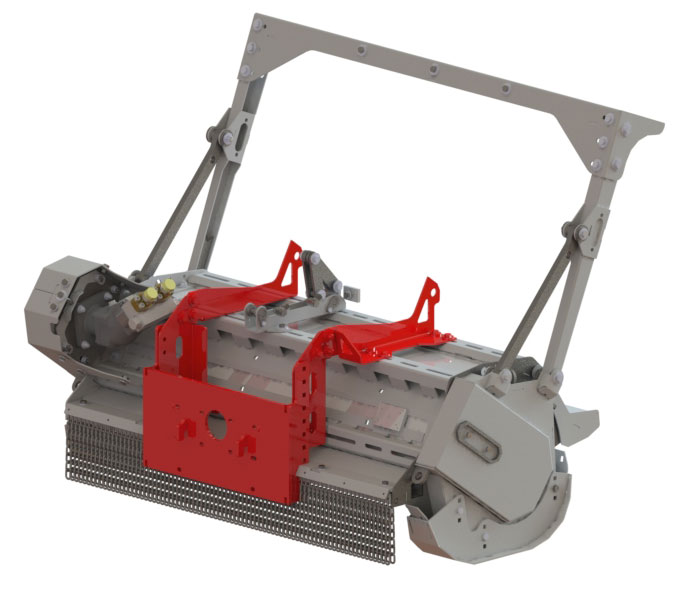

Undergrowth mulcher with hydraulic drive, for front attachment on wheel loaders, crawler track vehicles, large boom mowers or excavators

With its PH undergrowth mulcher humus brings to market a new powerhouse for green area maintenance and forestry work. The undergrowth mulcher with hydraulic drive has been especially developed for attachment on implement carriers with radio remote control. But it also suitable for other hydraulic carrier vehicles, e.g. for front attachment on wheel loaders, crawler track vehicles, large boom mowers or excavators.

Description

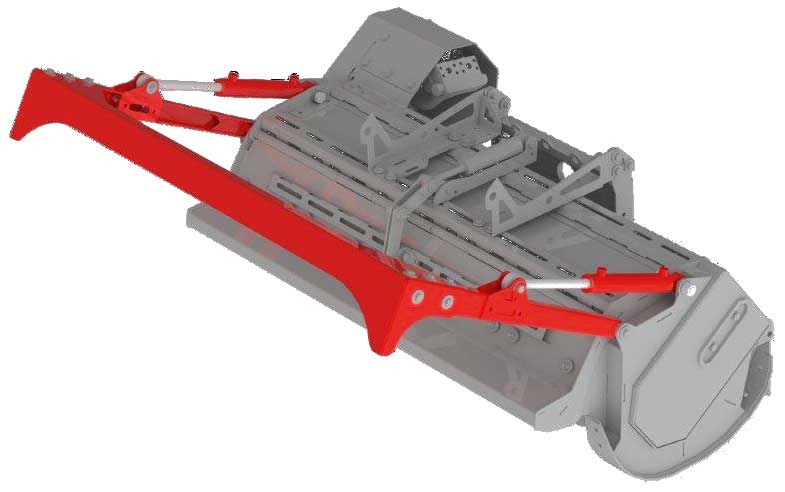

Flexible attachment

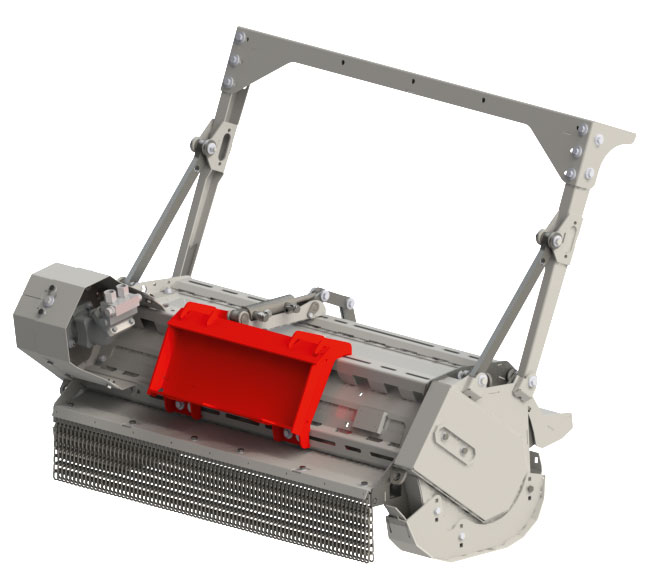

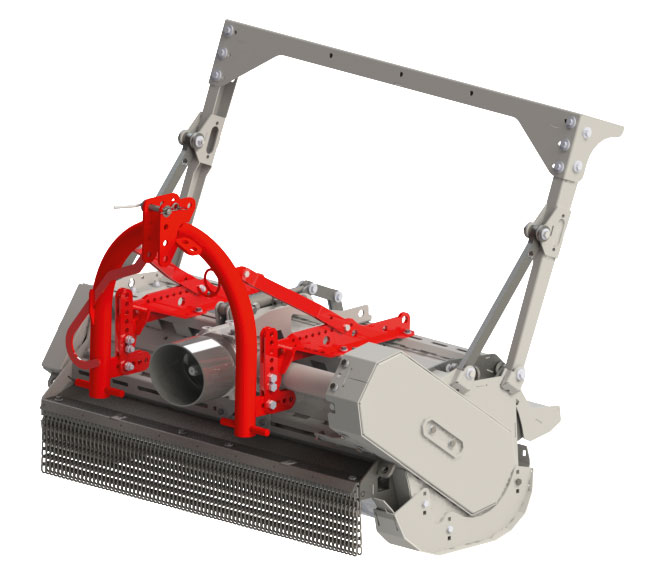

The housing has a system angle bracket for fast and flexible attachment on a wide variety of carrier vehicles. Optionally the humus PH can be attached with a three-point linkage Cat. II on PTO shaft-driven carrier vehicles in front attachment and rear thrust, with 540 or 1000 rpm. Flexible tool use (cutter systems) enables different applications and implementation conditions. The rotor’s tool configuration can be easily swapped out and matched to the application. The hydraulic front flap with counter-cutters is standard equipment. The counter-cutters in the machine ensure better reduction of the mulched material.

The housing of Hardox steel promises a long service life and is designed for professional use. An ingenious tool system guarantees an optimal cutting pattern: Ideally suited for green area care and forestry work, for rough terrain; it mulches undergrowth and branches without any problems.

Well proven range of use

- Mulching of undergrowth and scrub

- Ditches and embankments

- Area management and landscape management

- Municipal deployment

- Maintenance of bushy areas

- Recultivation

- Infrastructure measures

- Line maintenance

- Biotope maintenance

- Embankment maintenance

- Renaturation

Basic equipment

- Housing with system angle for quick and variable installation on the carrier vehicle

- Overload protection by flexible V-belt drive

- Large tray of mulch

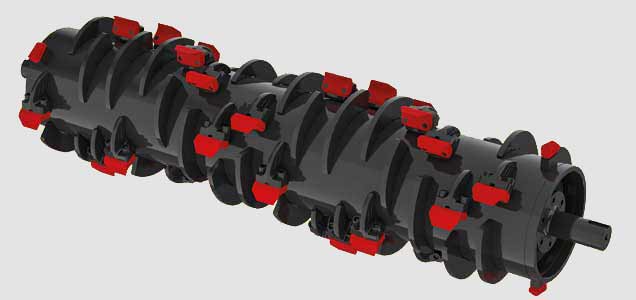

- Rotor tube diameter 450 mm Axial piston motor or gearbox independent of direction of rotation for 540 rpm oder 1,000 rpm

- Hydraulic maintenance cover at the front

- Housing of Hardox® wear plate

- Interchangeable skids of Hardox® wear plate

- Rotor with cutting depth limitation

- 2 interchangeable counter-cutters in the housing

- Cutting height adjustment up to 50 mm over skid

Accessories / special equipment

- PTO (part no. 800.11.004)

- Feeder valve 34 cm3

- Feeder valve 64 cm3

Technical data

PH 125 | PH 145 | PH 160 | ||||

|---|---|---|---|---|---|---|

| Blade systems B70 / B80: | pcs. | 26 | 30 | 28 | ||

| Working width: | m | 1,25 | 1,45 | 1,60 | ||

| Overall width: | m | 1,45 | 1,65 | 1,80 | ||

| Power requirement* : | from kW / hp | 40 / 54 | 55 / 75 | 63 / 85 | ||

| Axial piston motor: | l | 55 up to 110 l | ||||

| Rpm of PTO : | rpm | 540 or 1,000 | ||||

| Weight***: | approx. kg | 460 | 540 | 740 | ||

* The power requirement also depends upon the grass density and grass height *** Weight may differ according to equipment

The optimally balanced rotor with the B70 and B80 cutter systems ensures less wear on the bearings. The high rotor speed ensures high productivity and an optimal work result.

The rotor has a cutting depth limitation that prevents excessive depth in the material to be mulched, thus excessive reduction of the rotor speed is prevented. This a particular advantage with low-power carrier vehicles, in maintaining the rotor speed.

Special equipment

3-point linkage*

Cat. II Hydraulic side adjustment in connection with parallelogram adjustment, setting range ca. 400 mm (part no. 581.95.012)

Mechanical lateral adjustment in connection with parallelogram (part no. 581.95.041)

* Axial piston motor or gearbox independent of direction of rotation for 540 rpm or 1,000 rpm standard equipment

Hydraulic pressing device, 36 kg

Pressing device, 32 kg

Universal mounting (part no. 581.95.063)

Vermeer mounting (part no. 581.95.070)

3-point Cat. I (part no. 581.95.039)

Robocut mounting with swivel (part no. 581.95.040)

Skid-Steer mounting starting PH 135 (part no. 581.95.122)

Flange plate for Energreen (part no. 581.95.007)

Height adjustment H 250 / 190 mm adjustment (part no. 267.95.452)

Height adjustment H 250 P / 190 mm adjustment with pendulum balance (part no. 267.95.456)