PHLfor tractors from 80 hp

Attachment: Front or rear push via three-point linkage with KAT. 1 + 2

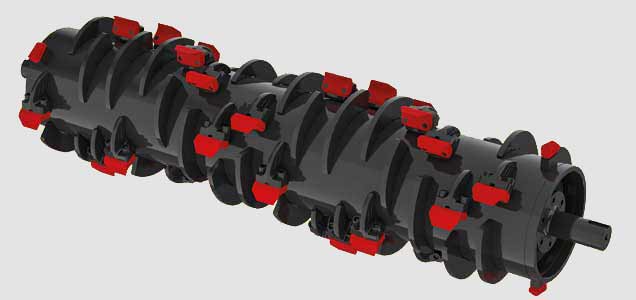

The „Lift-up“ pull-in roller feeds the mulch to the rotor. This increases the service life of the blade system, as the mulch is conveyed upwards from the ground, greatly reducing contact between the blade system and stones is greatly reduced. Due to the upward direction of rotation of the rotor, the mulch (sawn timber) is conveyed with high efficiency through the housing past the two counter blades in the housing and shredded.

The combination of forestry rotor with pull-in roller „Lift-up“ ensures a higher travelling speed and a significantly improved shredding result of the biomass.

Description

Flexible tool use

A flexible tool insert (blade systems) enables different applications and operating conditions. The tooling of the rotor can be easily exchanged and adapted to the application. The hydraulic front flap with counter blades is standard. The counter blades in the machine ensure better shredding of the mulched material.

The housing made of Hardox® wear plate steel promises durability and is designed for professional use. An optimal cutting pattern is guaranteed by a sophisticated tool system.

Well proven range of use

- For chipping large quantities of wood and roots

- In orchards and citrus / olive groves.

- For wood thicknesses of up to approx. 25 cm.

Basic equipment

- Gearbox independent of the direction of rotation for 540 or 1,000 rpm.

- Housing made of Hardox® wear plate

- “Lift-Up” pull-in roller, left/right (speed varies depending on additional control unit: from 40 l/min to a max. of 75 l/min, 226 rpm)

- 2 interchangeable counter-cutters in the housing

- Three-point frame, cat. 1 and cat. 2

- Mechanical lateral adjustment + parallelogram adjustment, setting range: approx. 40 cm)

- Flexible V-belt drive for overload protection

- Spreads mulch in a wide path

- Interchangeable skids made of Hardox® wear plate

- Skid for setting cutting height

Special equipment:

Hydraulic side adjustment

Technical Data

PHL 160 | ||||||||

|---|---|---|---|---|---|---|---|---|

| B70 / B80 blade system: | pcs. | 28 | ||||||

| Working width: | m | 1,60 | ||||||

| Overall width: | m | 1,80 | ||||||

| Power requirement* : | from kW / hp | 63 / 85 | ||||||

| Axial piston motor: | l | 55 to 110 l | ||||||

| PTO shaft speed : | rpm | 540 or 1.000 | ||||||

| Weight**: | approx. kg | 910 | ||||||

* The power requirement also depends upon the grass density and grass height *** Weight may differ according to equipment

Skids for adjusting cutting height

Rotor diameter: 450 mm, with cutting depth limit

Roller with wiper and gear wheel for smooth operation.

The optimally balanced rotor with the B70 and B80 cutter systems ensures less wear on the bearings. The high rotor speed ensures high productivity and an optimal work result.

The rotor has a cutting depth limitation that prevents excessive depth in the material to be mulched, thus excessive reduction of the rotor speed is prevented.

This a particular advantage with low-power carrier vehicles, in maintaining the rotor speed.

Click for details